120623 Sachi Station Small Layout

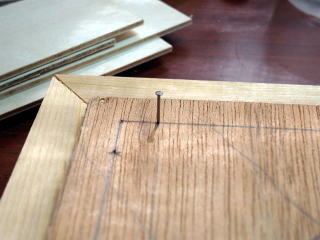

I paint a cut end part with adhesive and make an end frame in Tucker

It is glued veneer together by the reinforcement of the power pack mount.

This one-touch clamp is quite convenient

I make a smoothly planed board with course veneer.

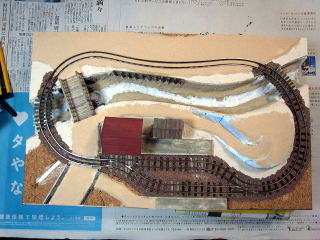

The topography has orthopedic treatment with the plaster which I mixed dust with

I draw wiring for streetlights in 0.2 Teflon line

I plaster a plaster

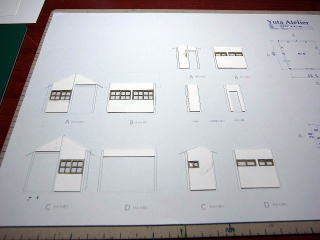

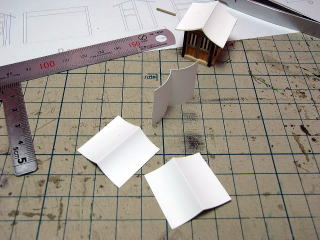

I arrange each part for a plan and confirm it This laminates hair to the shrine roof of the Shinto shrine and adjusts thickness and is examining it

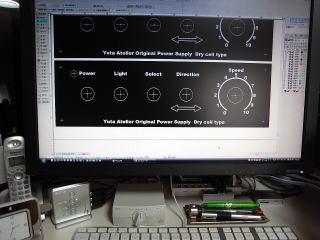

Set a dry cell; and ...

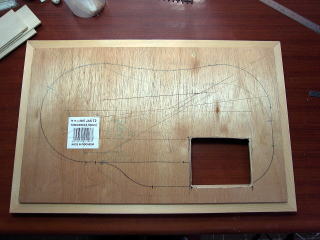

I describe a track position in 3 millimeters of veneer of the surface of the earth part

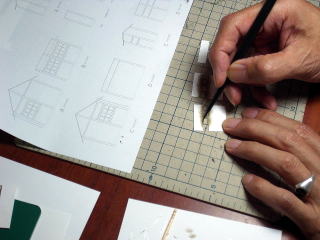

Introduction of a work process

Work No.120314 NOBI HANAMI Rail way

I finish an end in this way this time.

I color a grassy place part it

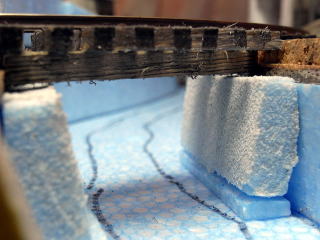

I bury wood flour clay in the track central part

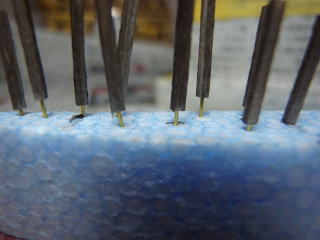

I paint a foot in charge account vermilion in a brass line

I prepared for the offertory box

Set an accessory

Drainage pipe setting

Retaining wall of the woody bridge part

I dig a drainage and am crowded

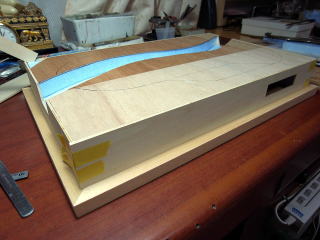

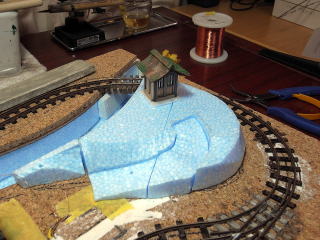

I get a hill part fixed with a styrene board

I put a woody bridge provisionally and do it and am confirming position relations

I glue a takeoff together

I glue the railroad tie of the bridge part together

I put it provisionally and do structure and look at the state

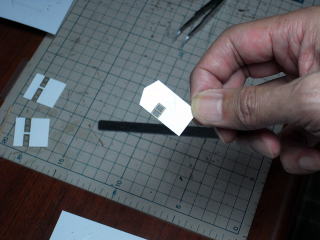

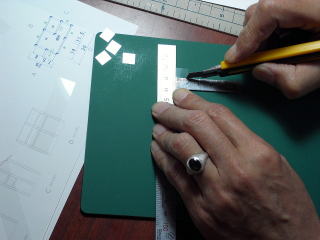

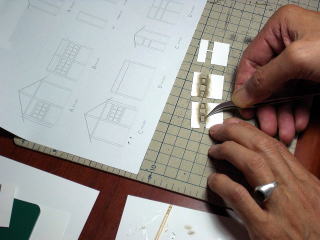

I cut a glass part to a housing part

I apply adhesive

It is glued together by the window housing part part

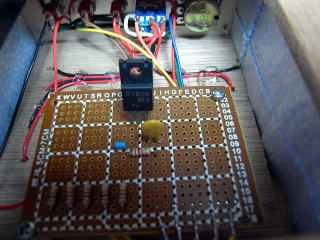

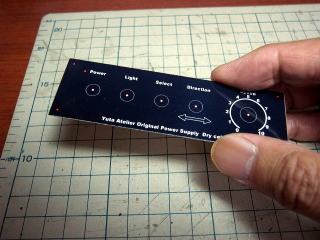

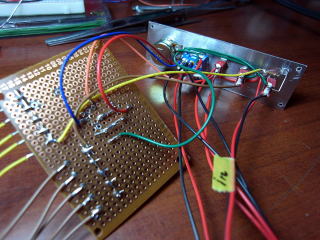

Power pack and the Control Panel which were completed

I cut a tap for panel installation

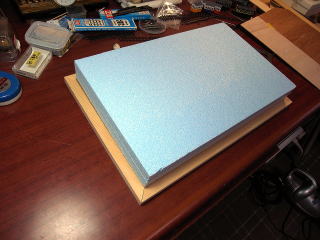

I make a layout base with hinoki squared lumber and China veneer.

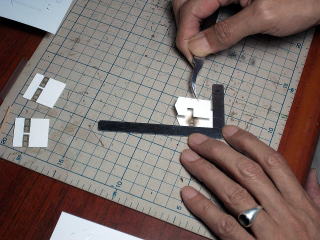

I cut it and pin hinoki squared lumber on 45 degrees and make finish

There is not the cutting position with the pencil, and is a cutter; marking

gauge

Is a rest room, the thing which do not see to the inside if install it,; but ...

I put books like a point and put it overnight.

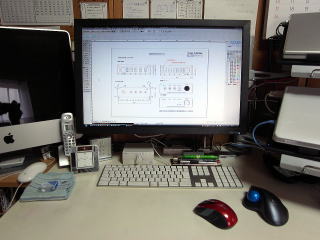

I design Control Panel by CAD softwareware.

The state that finished the road part

I attach a power pack base to a layout

I paint four times and repeat it in total and seem to finish it.

I paint it in a mahogany color.

I glue a smoothly planed board together in fast-dry bond.

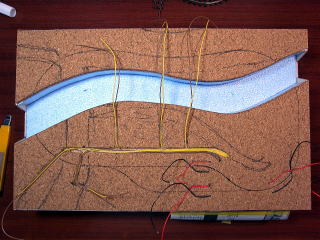

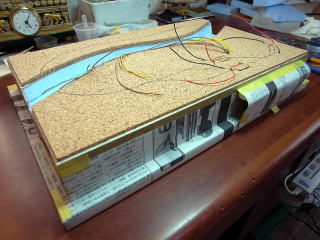

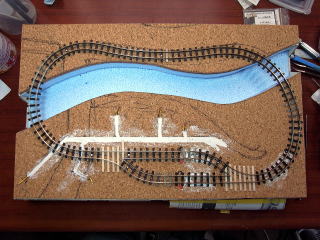

I draw a river and a track position on the cork sheet

The veneer of the surface of the earth part cuts for Kawabe, too.

I cut one piece of upper part of the styrene board and make for Kawabe.

I paint with production mat medium of the stone wall

I stick a pebble

The stone wall which was finished

I make a TORII

This is an intention of the bells )↓

I make a ditch after the painting at a bottom

I glue a meeting place measure and a sulcular cover together

I paint with mat medium earlier so that ballast is not scattered and sprinkle ballast. The adherence is mat medium water solution; (for mat finish)

I install wooden sand guards

A bridge and woody bridge of the railroad line

I sharpen plastic and have orthopedic treatment, and the insulation part adheres. I decide the rail of the turnout part by goods alignment, and it is soldered a brass board by a retainer.

I attach it to a doorknob

I bury wiring to each structure and flatten the surface in pate

Pate is in condition I bury it, and to have done it

I mask it in a makeup part for layout making.

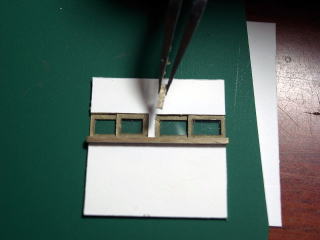

The drawing figures that is structure is CAD,

and the cut is C.R.

I attach a battery box

The state that has begun to draw a lead on the surface of the earth

I go while I make a hole in a panel, and a production soldering iron is one's own controller, and controlling the main body of power pack.

The luster is finished neatly well, too.

I glue a cork sheet together. The end share applies adhesive well not to become alienated

I cut styrene (20 millimeters of *2 piece of thickness stack) of the base

I cut 3 millimeters of veneer for the surface of the earth

I open a power pack installation part

Is one size small and sticks 5.5 millimeters of veneer.

I lower this part by approximately 1 millimeter from a track surface and finish it

Because I am slightly lonely, I add a bus stop

The drainage is expressed in gel medium

The structure illumination is OK, too

I dig into some middle parts of the river.

I fix a woody bridge

It is glued a sash together by a wall part

I apply a plaster on the part which the river dug into

It is glued 2 millimeters of thickness styrene boards

together by a road part

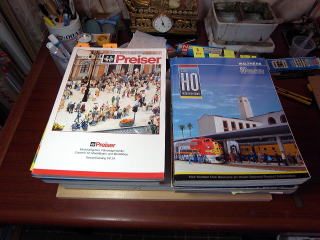

Please look at the direction with the interest which has not published the portion which overlaps with the contents introduced

by SAKURA Railway also there.

I cut it with angle limit jig and an exclusive saw

I mark it in a punch to make a hole for installation. (this automatic punch is convenient)

I make a fence

I attach a foot in 0.3 millimeters of brass line

I mask a track of the combination orbit

I ride a thing of 5.5 millimeters of thickness veneer degree if I can put it on the whole.

The cork sheet cuts for Kawabe, too.

It is glued a styrene board and 3 millimeters of veneer together by a layout basis.

I put books on the top and put it overnight.

I fix the veneer with adhesive and a nail well.

The photograph explains the process to completion.