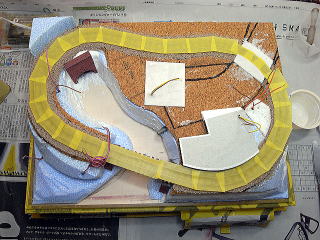

I make a layout base with HINOKI wood squared lumber and SINA wood plywood.

(because I have begun to record it since a bass is done,

there is not the processing photograph of the base)

If ballast dries, I mask it in a track

I fix deck garters and a supporting beam, a sewage pipe and get the topography fixed with a plaster

I apply the plasters which I mixed material of a plaster and the soil with on the important points

I mask it in a makeup part of the base to produce a diorama.

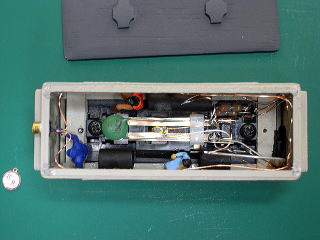

Because the power pack operates every process and must confirm it

I mask it in the shape of a cover.

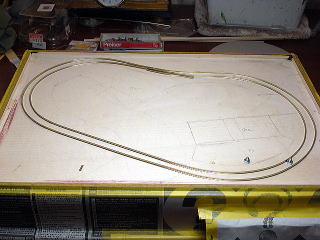

It is hard to look with the photograph,

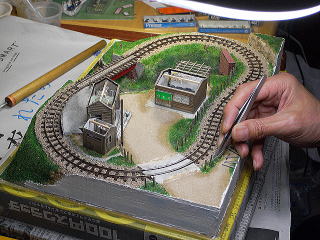

but draws track placement and the positions such as buildings.

I paint it with color varnish (mahogany).

I paint four times and repeat it until finish.

It is completion of the water in this

It is the last finish. I express a wave in gel medium of the soft type. I describe the wave of the river in a right angle for a flow. (by the way, the sea does it parallel to a bank)

The second water is resin which colored Green. I pour it and stiffen this for 後 24 hours. The depth of the color is made by repeating two colors

I pile gel mediumof the EX type to the glasswork and tear off by hardening, one of them and attach it to the sewage pipe

I make the spray in same gel medium.

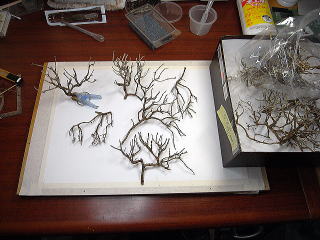

It is the preparations for cherry tree. Because I seem to be able to just use the bark for a cherry tree, I use this this time. (the thing which I dried after the choice for half a year, and stored the dead twig of the rosemary which I brought up in a garden)

Soil moiety of the ground I push the model in JIGU, and the piling-stones part comes

It is hard to look a little, but to wear a noren

I bury piano wire of 0.3mm in a core

In the building side of 0.3mm pierce it, and place it, and is crowded, and adhere in superglue

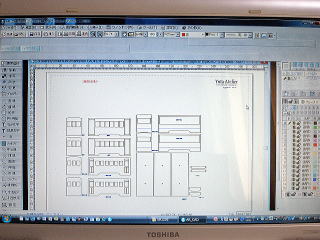

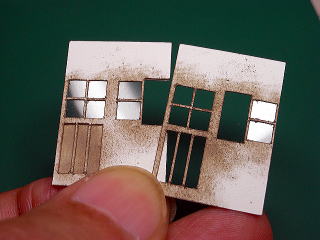

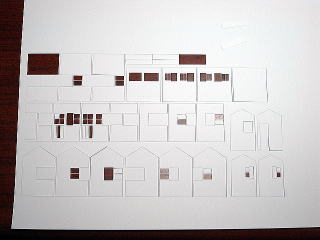

Before constructing a building,

it finishes paint of a fittings portion.

A

B

C

D

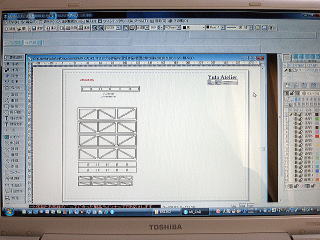

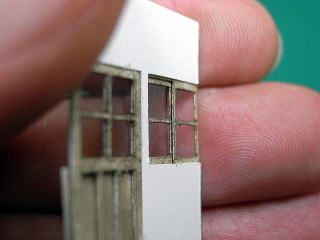

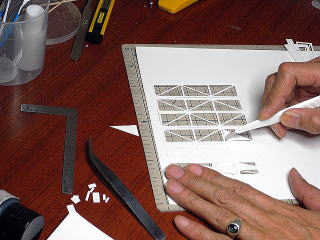

Glass is pasted up inside each window portion.

If the hope (it is thickness) of the fittings of a common residence is

made into 1/87 30 mm, it will be set to about 0.35 mm and will serve as

a result almost

near an absolute size.

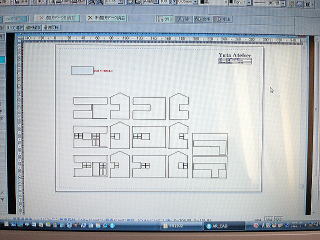

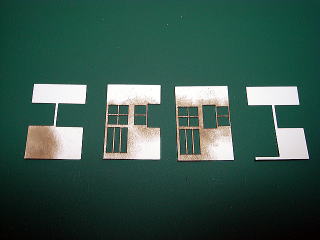

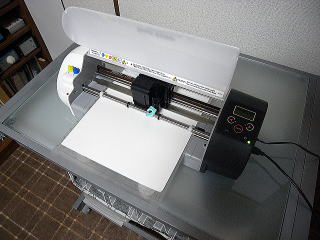

If a design of structure is possible,

I clip it out with a cutting machine

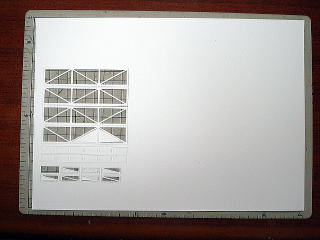

The paper which I clipped out

The people finish it with paper for the painting smoothly.

I prepare a part of the spray in gel medium of the extra heavy type and stick it on a dropping part of the drainage

The third resin is transparent. Depth of the water comes out this time by pouring this (this is because range of resin thickens). ・ which rigidifies this for 24 hours

It is the first water container. I wait until the first pours colored resin into blue (I perform it four times) and stiffens for 24 hours

The cherry blossoms glue by little that is aSILFLOR together with tweezers

The material of the grass is a SILFLOR,, too. By one stock adheres and does it

I bond a pebble to both sides of the river and finish it with the coloration of the bottom of a river

I color all parts it faintly

I harden powder with liquid adhesive

All the delicate parts of all structure reinforce it in this way

I complete a sash before completing a clapboard to

an outer wall

One of the wall surface is completion in this

I clip out the part which does not completely fall out here and there with a medical female

I let I pour each dry part and compete with adhesive

Tea house

Iron bridge

Vehicle

I paint a track in the state that got rusty.

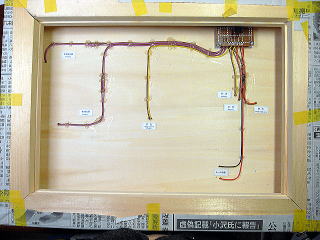

I fix electric wiring.

I open a lead for illumination in each place.

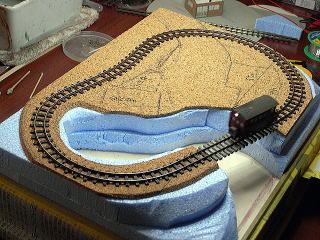

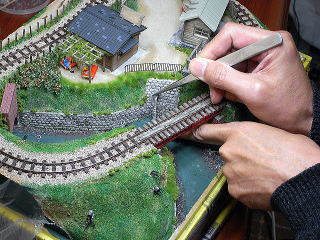

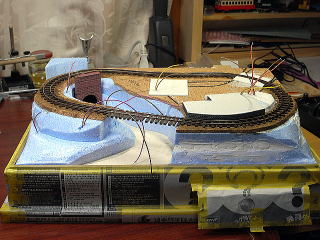

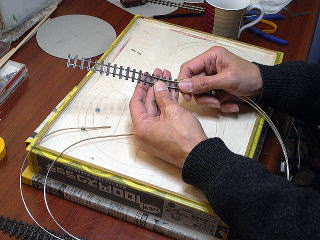

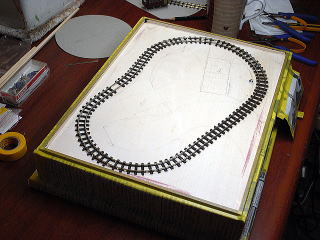

I bend a rail according to the placement figure.

I put a railroad tie through the track.

Put it away through a railroad tie and

put it to the board and confirm it.

How to make makes the vehicle like a building. The specifications power uses a product made in KATO A headlight, tail lamp, the indoor light incorporate tip LED A driver, two passenger rides As for the head mark of "the flower viewing", disassembly is possible

Work No.120314 NOBI HANAMI Rail way

Introduction of a work process

I fix the building at this stage

Because I do not yet attach it,

the inside is seen on the roof well

If the painting dries, I incorporate original power pack.

The power pack forgot to take a photograph in a production process

I solder a lead to LED of the illumination in the building

I bury a stake along the track

I set up wire and paint it in rust

The broken stakes keep a change made

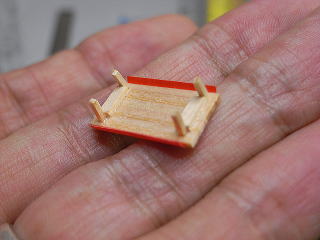

Folding stool (SYOUGI) to put under the wisteria trellis

I sprinkle ballast.

I hang down liquid adhesive and harden ballast.

I model the topography in a styrene board and stick cork.

I change the railroad tie of the iron bridge part.

I solder a feeder.

I make a trial and am a check and

the confirmation of the run.

The photograph explains the process to completion.

I finish a flower viewing visitor to employ under the wisteria trellis

The left photograph is a cake ( MANJU )

to put on the dish ()

To a teapot and a teacup, a beer bottle glasses

I fix an accessory to the folding stool